![]()

Advanced Isolation and Testing Services Sdn Bhd

Advanced Isolation and Testing Services Sdn Bhd

C-2-06, Street Mall, One South

Jalan OS, Taman Serdang Perdana

Seri Kembangan , Selangor D.E. 43300

Malaysia

ph: +603 8959 8231

fax: +603 8957 9231

contact-

Pipe End Plugs

Pipe End Plugs

Pipe End Plugs

Pipe End Plugs are used primarily in construction and fabrication of the oil, gas and petrochemical industries to cap open ended pipe, pipe spools or piping systems facilitating hydrostatic leak and strength tests. Pipe End Plugs provide many benefits by reducing time and costs compared to traditional methods of welding end caps to the pipe spool. STATS range of Pipe End Plugs cover two separate products the I-PEP™ which fits internally to the pipe and the E-PEP™ which grips the pipe externally.

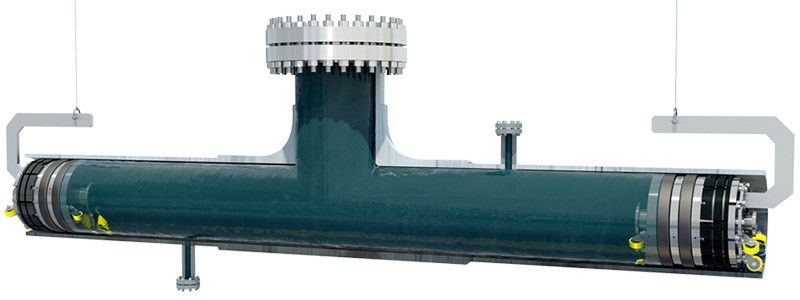

E-PEP™ – External Pipe End Plugs

The E-PEP™ series of patented Pipe End Plugs are fitted to the pipe end and hydraulically actuated, gripping the pipe externally. The introduction of hydraulic set pressure activates a mechanical lock assembly that grips the OD of the pipe whilst simultaneously energising an elastomeric seal in the ID. This allows the pipework to be quickly and efficiently pressure tested with minimum preparation to the pipe end and no remedial work after the E-PEP™ is removed. A through port allows the system to be filled and pressurised or vented through the E-PEP™. To remove the E-PEP™ from the pipe end, hydraulic pressure is applied to the unset circuit. This retracts the lock assembly and de-energises the seal, allowing the tool to be removed.

The E-PEP™ range covers pipe sizes from 3” to 30” and compliments the I-PEP™ range but with the advantage of not being limited to nominal pipe sizes as the selection of tool is based on the internal diameter of the pipe being tested.

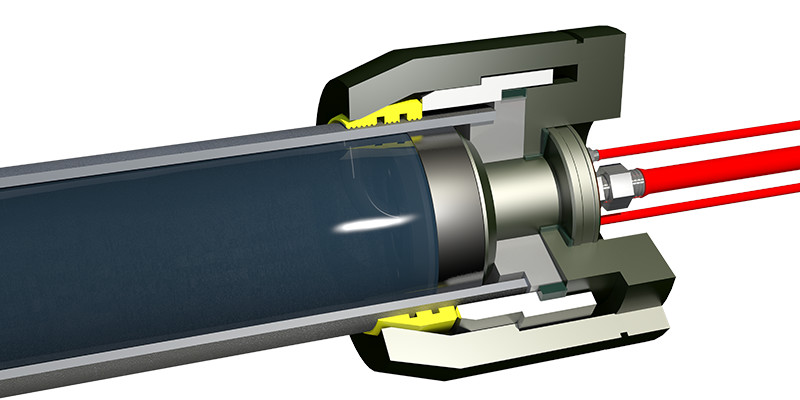

I-PEP™ – Internal Pipe End Plug

The I-PEP™ series of Pipe End Plugs are inserted into the bore of the pipe and hydraulically actuated. These tools internally grip the pipe allowing hydrostatic pressure tests to be quickly and efficiently performed. The introduction of hydraulic set pressure activates a mechanical lock assembly that grips the ID of the pipe whilst simultaneously energising an elastomeric seal. This allows the pipework to be pressure tested with minimum preparation to the ID of the pipe and no remedial work after the I-PEP™ has been removed. A through port allows the system to be filled and pressurised or vented through the I-PEP™. To remove the I-PEP™ from the pipe, hydraulic pressure is applied to the unset circuit, retracting the lock assembly and de-energising the seal allowing the tool to be removed.

Hydraulic I-PEP™ cover pipe sizes from 30” to 42”, however for sizes ¾” to 2” mechanical tools are used and fitted with securing clamps for added safety.

All Pipe End Plugs are designed in accordance with STATS engineering standards (based on international codes) to facilitate testing in accordance with ASME B31.3 and similar piping codes. Sizes are based on standard pipe with interchangeable seals to cover ASME B36.10 and ASME B36.19 schedules.

Operator Benefits

- Operators save time and reduce costs associated with welding / cutting end caps.

- Timely completion of construction and fabrication activities.

- Sale or rental options available, complete with full ancillary equipment.

- Fully certified client training provided by highly trained STATS personnel to support Pipe End Plug hire.

Key Features

- Eliminates the need to weld caps or flanges to carry out a leak test.

- Simple, straight forward installation and operation.

- Installed and activated in a matter of minutes.

- Large section high quality elastomer seals ensure a leak tight seal.

- Test pressure applies differential pressure across the tool and ‘self-energises’ the lock and seal ensuring fail-safe operation.

- Designed with generous radial clearance to cope with typical internal obstructions such as weld beads, ovality, etc.

- Non-destructive, does not damage the interior / exterior wall of pipes or vessels.

- Internal and external grip lock assembly applies even linear and circumferential grip load around the host pipe, eliminating localised material deformity and localised stress fractures.

- Suitable for use with most test mediums (liquid or gas).

- High performance elastomer seals provide excellent radial expansion and relaxation properties, even after many operating cycles.

- Optimised through port allows efficient fill or vent of the test medium.

- Reduces the environmental impact by negating the need for sacrificial end caps and welding consumables.

- Robust construction ensures years of trouble free operation even in the harshest environments.

- Suitable for installation in horizontal, vertical and inclined piping.

Need More Information?

For further information regarding the services and solutions we are able to provide please email your enquirey to:

Copyright 2018 Advanced Isolation and Testing Services Sdn Bhd. All rights reserved.

Advanced Isolation and Testing Services Sdn Bhd

C-2-06, Street Mall, One South

Jalan OS, Taman Serdang Perdana

Seri Kembangan , Selangor D.E. 43300

Malaysia

ph: +603 8959 8231

fax: +603 8957 9231

contact-